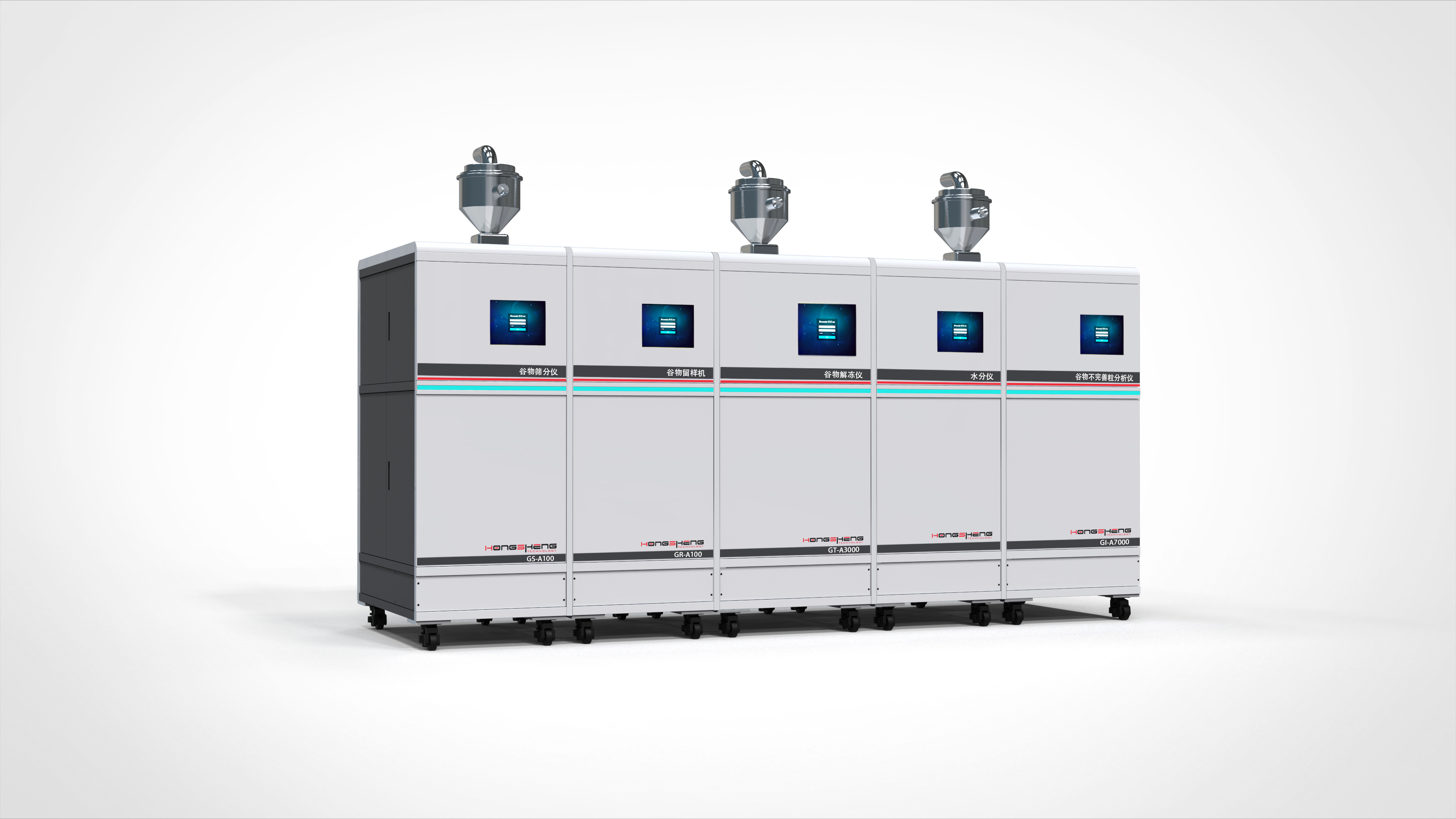

Fully Automated Grain Quality Inspection Platform- Series A

Applications:

Features and Benefits:

Industry pioneer with various applications, especially in frozen grain; the units can be customized based on customer needs

Available for corn, wheat, paddy, soybean and peanut testing

"Kernel by kernel analysis and group weighting" technology exclusively offered across the market

Technical Specification:

Product model

Fully Automated Grain Quality Inspection Platform- Series A

Application

Available for corn, wheat, paddy, soybean and peanut testing

Parameters

Unwanted objects, moisture, protein, unsound kernel, etc.

Units

Grain mixed and separated analyzer, grain sieving analyzer, milling yield analyzer, unsound kernel analyzer, moisture analyzer, grain thawing analyzer, etc.

Dimensions

L*W*H 4200*1400*1700mm

Power

25kw

Specification

Wheat: unsound kernel (insect damage, disease spots (black germ, fusarium rust), damage, sprouts, mold), impurities, moisture, bulk density, impurities, protein, wet gluten, hardness index and sedimentation value

Corn: mildew, unsound kernel (insect damage, lesions, breakage, sprouting, mildew, heat damage), moisture, test weight, impurities including impurities of similar size, etc.

Paddy: rough grains, rough rice rate, polished rice rate, unsound kernels (unripe, worm-eaten, diseased, sprouted, moldy), yellow rice, intermixing rate, mixed grains, moisture, impurities, etc.

Soybean: unripe kernels, damaged kernels (insect-damaged, diseased, sprouted, moldy, heat-damaged), broken kernels, impurities, etc.

Analysis time

5 min/patch

Sample size

Wheat and paddy: 50g; Corn and soybean: 200g

Recommended product

Recommended products